Project: Vega Install & electrical panel re-location

Sector: Municipal

Role: Prime Consultant

Description

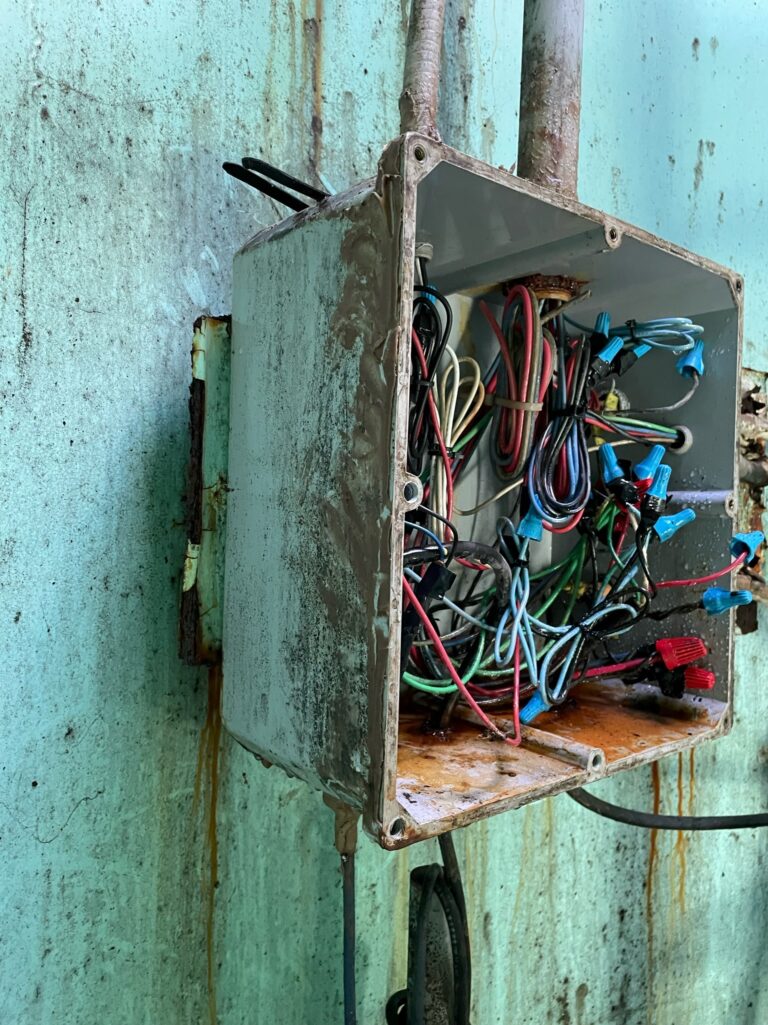

We cut, threaded, and bent all the aluminum rigid conduit at a shop and attached all the Meyers hub connectors. We then welded struts to pipe clamps and primed and painted. We pre-assembled the junction box, attached the back pan, din rail and panduit at the shop. Once all the pre-work at the shop was completed, we loaded up the service truck and prepared for travel. Once on site, we did a walk-thru, filled out the necessary paperwork and began work by mounting the new junction box. We drilled through holes at the top of the wet well enclosure and installed rigid conduit through holes, using a watertight seal connector. We entered all conduit into JB and attached the ground bar. We pulled the new wires for the VEGA from the wet well to the main control panel. We programmed the VEGA and matched the switching points of the previous system to interface with the PLC controls in order to achieve pump control that works within the parameters of the flygt bulbs so that the alarms do not go off unless a system fault is occurring. The Vega was programmed to work within the coordinates and the function was tested.

We had the main power to the site turned off and verified there was zero energy. We disconnected all of the terminations in the existing junction box located in the wet-well and begin demo of all the wires. We labelled all the wires that ran back to the panel to ensure proper re-connection after new wires are pulled through the underground conduit and using the existing junction box. We pulled the new electrical wire from the panel through underground conduit and using the existing junction box as a pull box. We brought the new extended wires to the new above ground panel that is located outside of the wet-well in a waterproof enclosure. We re-connected all of the motor leads, heaters, float bulbs and the back-up pump in both the new junction box and on the control panel side. We metered out all terminations verifying that no wires are crossed using a continuity test. Once all the new connections are made and Vega is properly interfaced with the system we began commissioning the system. After commissioning of the system and verifying the pump control is within the pre-set parameters.